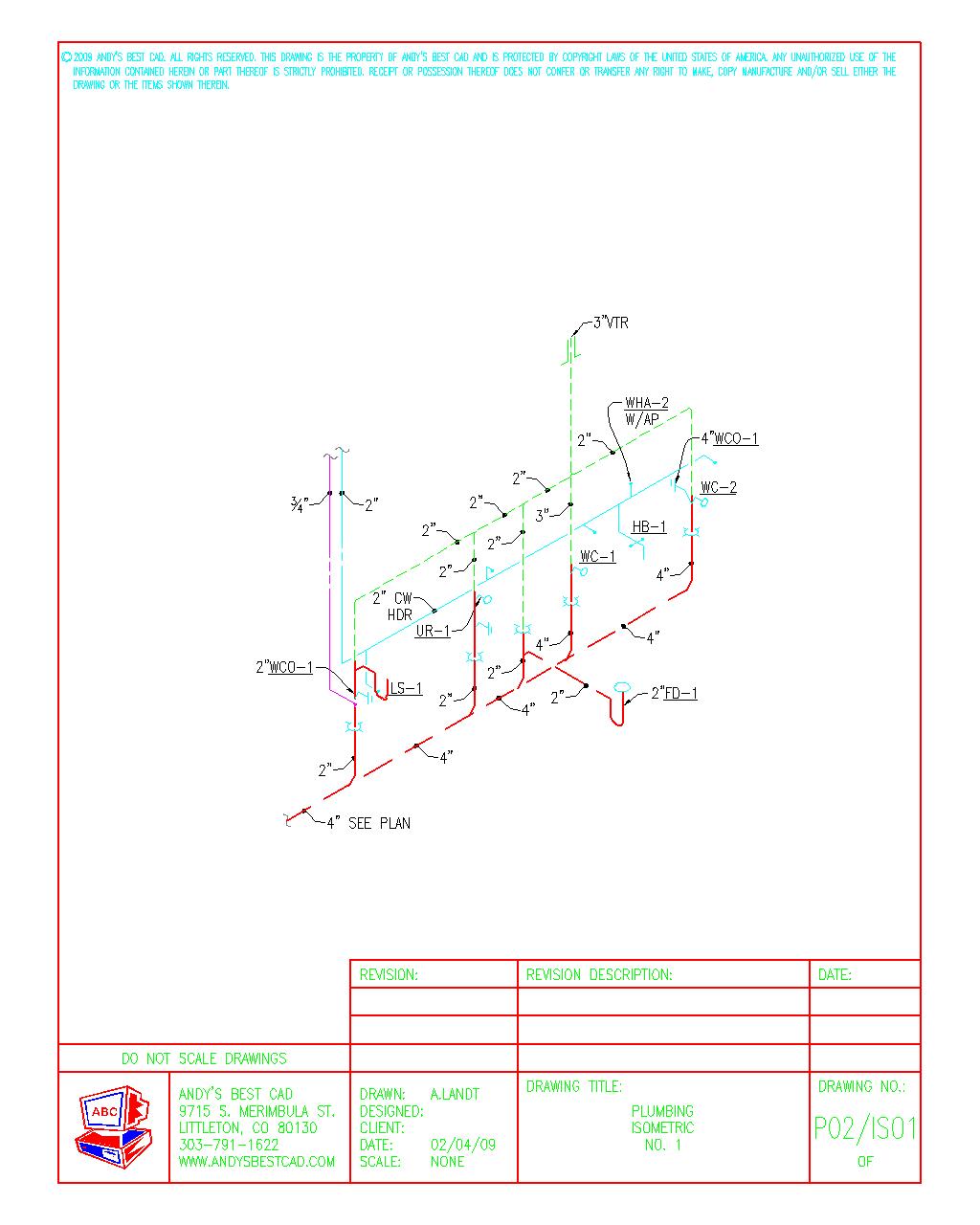

a very detailed diagram showing the processes happening within a plant, the involved equipment, and their interconnections.Ī set of standardized P&ID symbols is used by process engineers to draft such diagrams. P&ID is the acronym for “Piping and instrumentation diagram”, i.e. Difference Between ODM, OEM and OBM Production StrategiesĪ complete collection of the most used P&ID symbols for lines, piping, valves, instruments, pumps, compressors, pressure equipment and other mechanical equipment, and the PDF file for P&ID symbols to download WHAT IS P&ID?.Contract Risks: a Checklist for Exporters.HS Codes for Pipes, Valves, Fittings, Piping.Containers and Pallets: Sizes and Types.What are Incoterms? (ExW, FOB, CFR, CPT,…).5 Practical Ways to Finance Export Sales.

Process Instruments (Measurement Features).Non-Destructive Testing Types (LP/MP/UT/RX).The 7 Flow Meters Used in the Oil and Gas Industry.ASME B16.34 Pressure/Temperature Rating.Types of Gaskets for Flanges (Soft, Spiral, Ring Joint).Threaded Flange Dimensions EN 1092 (PN 6/16).Blind Flange Dimensions EN 1092 (PN 6/10/16).ASME B16.47 Flanges Dimensions and Weights.Socket Weld Flange Dimensions (ASME B16.5).Spectacle Blind, Flange Spade, Ring Spacer (ASME B16.48).Flange Isolation Kit for Cathodic Protection.Flange Pressure Rating Explained (and Charts).The 13 Types of Flanges for Piping Explained.Weldolet, Threadolet, Sockolet Explained.Socket Weld and Threaded Fittings (ASME B16.11).Types of Ball Valves (Floating, Trunnion).Valve Face to Face Dimensions (ASME B16.10).Types of Valves Used in the Oil & Gas Industry.ASME B36.10/36.19 Pipe Dimensions Charts.Pipe Sizes: NPS, Schedule, Length, End Types.Stainless Steel and Duplex Pipe (ASTM A312, A790).Types of Oil & Gas Pipes: Seamless, ERW, LSAW.

0 kommentar(er)

0 kommentar(er)